Drop by drop to better diagnoses

Written by

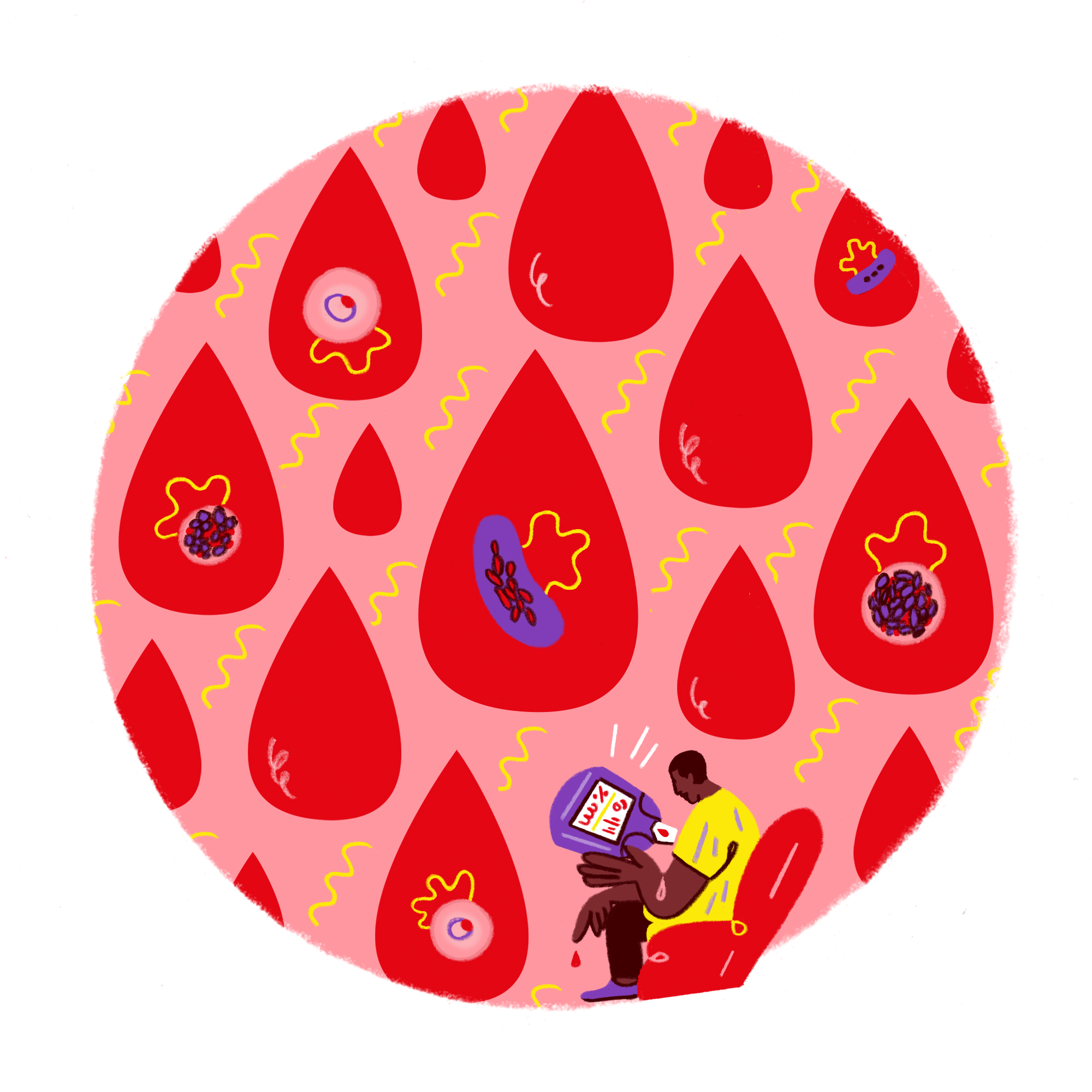

How a new biosensor could prevent malaria deaths

When it comes to battling infectious diseases, early detection is essential. Before prescribing adequate treatment, doctors should be able to quickly identify what kind of parasites the patient is fighting against. Easier said than done. Sometimes, a person’s life depends on only a couple of hours – but what if prevalent testing methods aren’t precise or fast enough? Gabriela Figueroa Miranda has been working on a user-friendly biosensor that will enable patients and doctors alike to identify specific malaria parasites in the blood.

What are aptamers and what do they have to do with battling malaria disease?

Aptamers are short single-strand DNA or RNA molecule sequences. Their most important characteristic is that they bind with high affinity to a specific target, like the biomolecules of malaria parasites. This is how our biosensor recognises malaria in the blood of patients. Aptamers are synthesised artificially. No experiment animals needed!

What is the standard of malaria detection thus far?

The standard is microscopy, which is time-consuming. Only a trained person can identify a parasite in the blood sample. There are rapid diagnostic tests that work like COVID tests, but they are less stable in higher temperatures and can only tell you whether you are infected or not.

How would your biosensor work?

In principle, it would work like a glucometre. The patient puts a drop of their blood on the sensor and can read their results from the screen of a small device. The sensor will provide extra information, such as the number of parasites present in the blood. Our device is more sensitive than any rapid test. We can detect as low as 50 parasites per microlitre. Thus, the result is not only qualitative but also quantitative.

… which is essential for choosing the proper treatment.

Exactly, our biosensor can detect various biomarkers in the same sample. That allows us to discriminate between different malaria parasites. This way, a doctor or paramedic will know which medication is required, and how much.

What needs to happen before rolling out the prototypes for the sensors?

In the beginning, I thought that we had everything ready to launch our sensor onto the market. I soon realised that we had developed a sensor at the lab scale, not a product for anybody to use on their own. We are currently working on optimising the design. Any person, not only doctors, should be able to use our sensor.

Was it always part of your research to develop something applicable?

It was not my aim to end up with a product, but – due to the promising results of my research – I realised its potential. The question of “Why not” kept growing bigger. With the help and support of my supervisor at Forschungszentrum Jülich, I successfully pitched my idea to my technology transfer department. They are supporting me financially. Together with my colleague Viviana Rincón Montes I have been working on the optimisation of the biosensor to make it more user-friendly. We are currently also writing applications for funding to support the further development.

What would you do with your first funding?

We want to go to the clinical trial, which are part of the certification for in vitro diagnostics. We need the certificate to prove that our product is effective. A part of the money would go to the investment in machines. It is important to standardise and optimise everything before going to mass production. It is not the same to fabricate one sensor in the lab as opposed to 100,000 in a production facility.

What is the day-to-day of your job?

I frequently check in with my research team, write applications, and attend workshops, such as the Young Entrepreneurs in Science Workshop. Each day, we learn more about building a startup. We are now participating in an ideation programme at RWTH Aachen that provides us with a coach to help us with our business model. In science, soft skills are not the main focus, yet they are essential for entrepreneurship. This is why I loved the YES programme. In the prototyping session, we learned how to build something fast to show to investors without having a finished product. The teamwork in the breakout sessions was a great chance to receive feedback.

How do you deal with the uncertainty of entrepreneurship?

I take things one step at a time, but of course, there are always many open questions waiting to be addressed!