A brighter future for solar

Written by

How a young startup aims to disrupt the solar industry with printable solar cells

The demand for solar modules is rising, but their production still relies heavily on non-renewable resources. Therefore, researchers turned entrepreneurs have been working on new efficient solutions to bring the sun’s energy to our outlets. Among them, a small team around Claudiu Mortan in Stuttgart, who combine a printing technique with the mineral Perovskite to develop lightweight and recyclable solar cells – which could even go up to space.

Claudiu, what stands in the way of powering the world on solar energy?

Imagine that just one hour of sunlight would be enough to power the world economy for an entire year! The issue is that manufacturing conventional solar cells involves high amounts of thermal energy to yield the highly refined elemental silicon used in the cells. By the way, a large portion of this energy still comes from coal. The energy payback time – the amount of time the solar module needs to produce as much energy as was needed to manufacture it – varies between one to three years. A conventional solar cell can last several decades, but it loses efficiency over time and is expensive to recycle. Solar cell production should become greener in the future.

Why are your Perovskite solar cells a better alternative?

Silicon is reaching its maximum efficiency. We aim to improve the technology and eventually exceed it. Perovskite solar cells have the potential of a low energy payback time of only several months due to their low-temperature processability. They can be easily recycled. You can dissolve the different layers that make up the solar module into different solvents and purify the materials. This way, you can reuse them according to the cradle-to-cradle model. The materials in our Perovskites are not only recyclable but also abundantly available. Silicon panels cannot be dissolved, and most likely a lot of them will end up as landfill because recycling is expensive.

What about the production process?

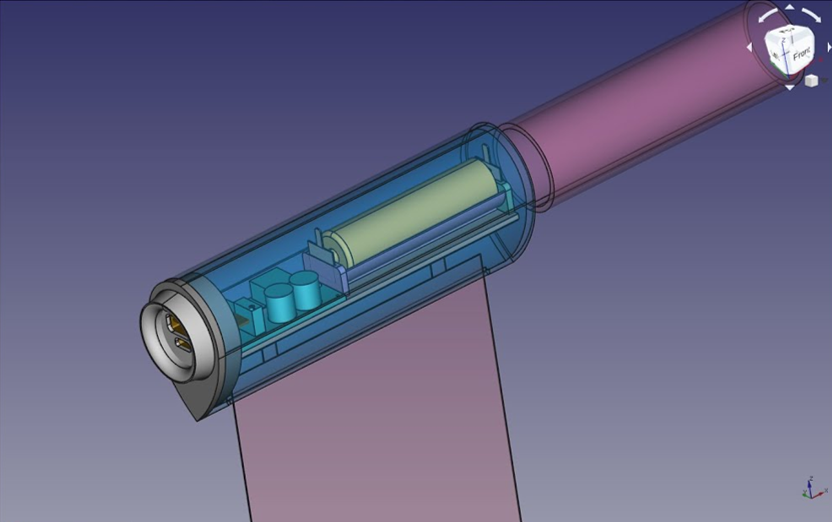

Our production process is at the heart of our innovation. We are developing a process for a slot-die coating method. It works like a 3D printer. Instead of a tiny nozzle, we have a wider slit. We press a liquid with our active substances onto a substrate, like glass or polymer foil. We want to dry the semiconducting films that make up our solar cells while recuperating the solvents for reuse.

What are some of the challenges of working with a novel material like Perovskite?

Because of its novelty, there is little actual data about Perovskites solar modules’ long-term stability. Within twelve years of research, Perovskite solar cells have already experienced an unprecedented leap of efficiency on a lab scale, but if we can’t get these solar cells stable enough in the upscaled production, no one will buy them. Our recipes include stable solar cell materials that need to prove themselves in our pilot production process.

If there was one wish you could make with regards to the startup landscape in Germany, what would it be? What do you need to succeed?

To be able to compete globally, we need faster access to grants for startups in Germany. Let’s look at how long it took us to write the application for the initial funding from EXIST. We have been working on the application since December. After the application, it will take three months to grant it. Altogether those are nine months of work without funding. The lengthy process aside, I am very thankful for EXIST! We will receive this grant without the obligation of paying it back. We will do our best to pay back the money in taxes later on. Another benefit of EXIST is that we will be able to use all the facilities of the university that we would not have access to otherwise. It allows us to tap into the research knowledge and infrastructure of all the institutes there.

Once you cleared that hurdle, what will you use the grant for?

We want to upscale the production process in a lab setting for building a larger prototype module. With further funding, we will work together with the InnovationLab GmbH in Heidelberg to develop a pilot production process. They provide different coating and drying modules for their roll-to-roll printing machine that we can configure according to our needs. There, we can customise our process, to find the best parameters for printing efficient and stable solar cells. Ultimately, we would like to buy our own production facility.

If all works out, where could we see Perosol’s solar cells in the not-so-distant future?

The opportunities are endless, but it is a challenge to realise actual products. How about making umbrellas with solar cells lining that you can take to the beach? Or tents with flexible solar cells for camping? These ideas are fun, but they would still need a lot of development time, being hard to realise. Ideas are like stars, they are abundant but hard to reach. Speaking of stars: our solar cells could be used on satellites, because of their low weight. It can cost up to $50,000 per kilogramme to launch payloads into space, so saving weight is crucial. You would be able to compress the solar cells and unfold them in space like origami. This would be a dream come true.

Luckily, you are not alone on your journey to achieve those goals. How did you meet your cofounders?

First, I contacted Prof Michael Saliba, a well-known specialist for Perovskite devices, and Director of the Institute for Photovoltaics at the University of Stuttgart. We know each other from different conferences and had spoken about a potential startup before. He was very happy to cofound Perosol. We are the first German startup to deal with this novel and amazing material class! Dr Chittaranjan Das is a good friend of mine and currently working as a postdoc at KIT. We are both science guys, so our startup coach Dr Jordi Mauri advised us to find a person with an economics background. It was difficult to convince somebody to join a startup and write a business proposal without any funds to show for. I wrote several job ads and invested a lot of time in finding somebody who is a proper fit. Then Dipl.-Wirt.-Ing. Elmas Yigitbay came along. She has more than 10 years of experience in the B2B market and believes in the Perosol project. She will help us find the market on which we can launch our solar cells in rough amounts.

How did you know that you want to launch your startup?

I do have a business mindset. I have always wanted to have a business, which is why I signed up for Young Entrepreneurs in Science. The programme motivated me a lot. The question “How much startup is in your PhD?” spoke to me. We were discussing different ideas for Perosol in the course and now we are making it a reality •